Ammerlaan-Sosef has commissioned WPS to further update and improve its current sorting and shipping buffering system. WPS is working vigilantly to get the job done within the allotted time slot and get all new wishes implemented.

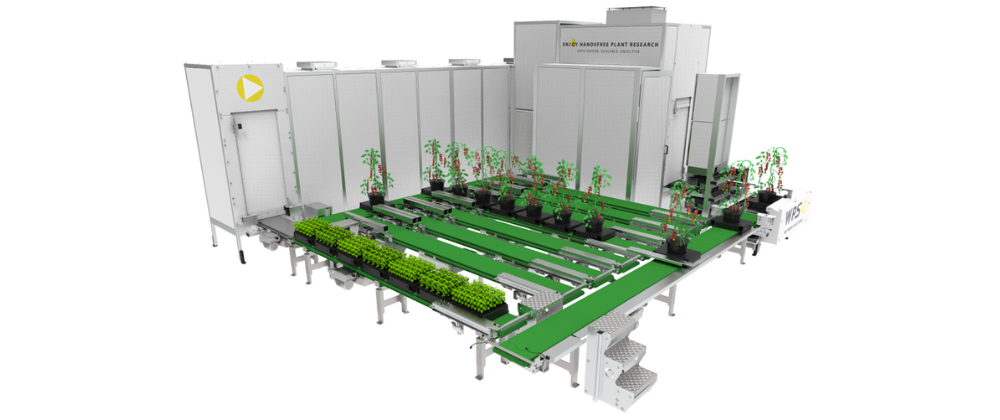

Expansion and upgrading the buffer

The number of tracks of the renewed buffer system will almost be doubled and for a large part will be a continuation of the existing buffer. In this new setup Ammerlaan-Sosef will be able to water the plants in the gutter tracks of the shipping buffer. Furthermore the buffering system will be integrated and connected to last years installed SmartFlo system.

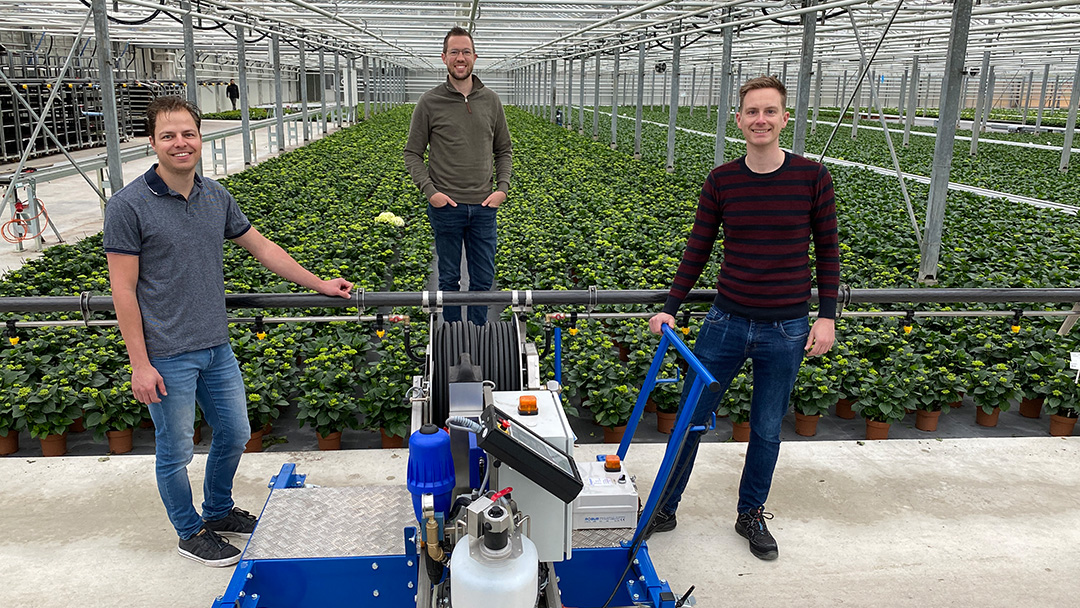

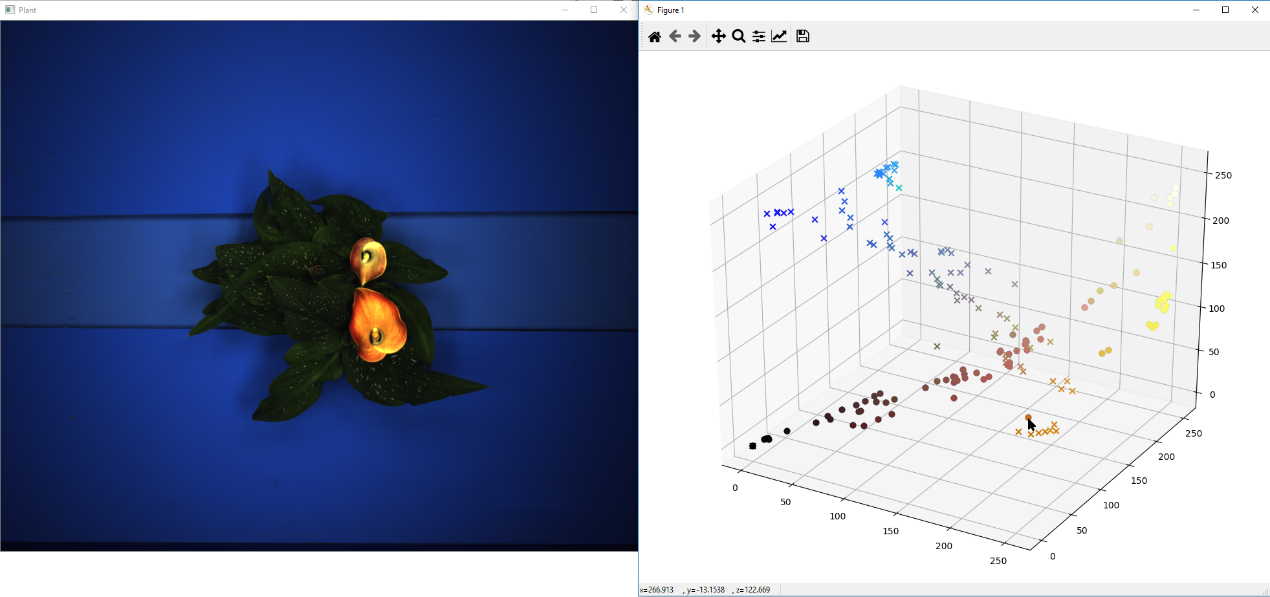

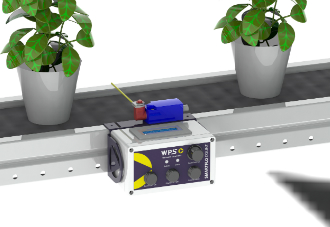

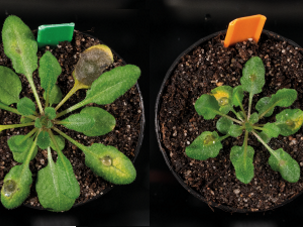

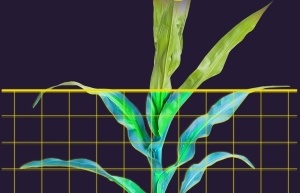

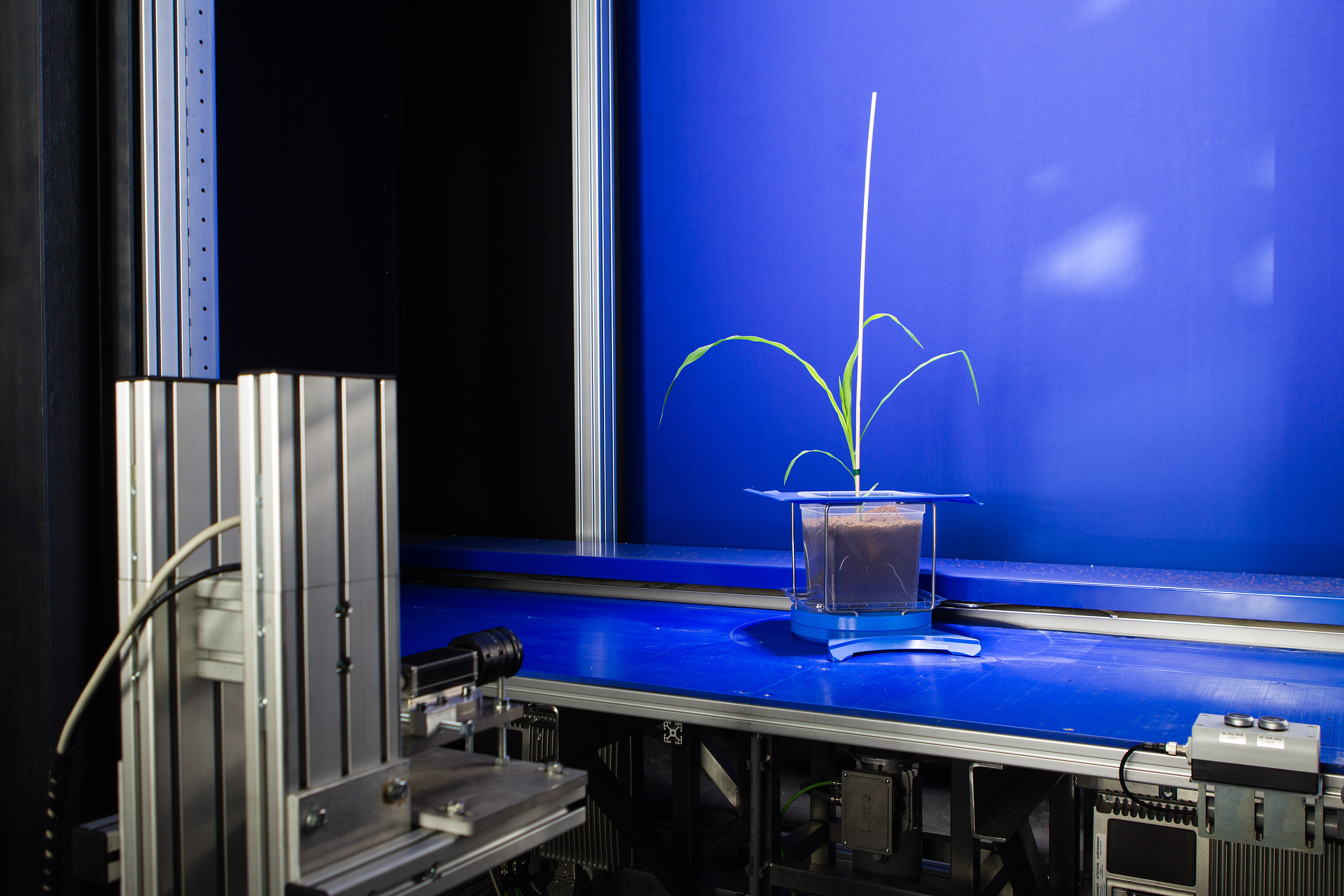

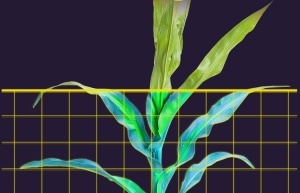

Sorting with Plant Vision technology

Plant Vision technology in combination with WPS’s software analyzes at high speed large numbers of plants. Plants can be sorted based on characteristics, such as size, color and species. Next, the sorted plants are automatically transported to assigned buffering tracks and packing stations.

Part 2 of the project: Packaging Line automation

Besides upgrading the sorting buffer, Ammerlaan-Sosef has even more ambitious plans in the form of automating the packaging line. This automation consists of a sleeving machine, a Smart Placing robot which automatically places plants in an assortment of trays and an automatic tray de-stacker called Smart Destacker, which can de-stack trays of various sizes. In the next few weeks we will keep you updated on this project as well.

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)