De Lier, Netherlands – May 2025

Despite ongoing economic turbulence in global markets, WPS has once again proven its resilience and innovation strength by securing two landmark contracts in the past two weeks—affirming its role as a trailblazer in horticultural and plant research automation.

Spring Meadow invests in automated delivery system

The Dutch-based horticultural technology leader has secured the first-ever automated delivery system for ornamental crops in the North American horticulture market, a groundbreaking milestone that sees WPS expanding its footprint beyond just logistics solutions (internal transport) in North America. The automated delivery system, which sorts the plants and takes the selected orders to the packing stations instead of having employees collecting the plants manually, will be installed at Spring Meadow Nursery in Michigan, signaling strong demand for advanced automation solutions across the Atlantic to address labor challenges; the next step towards hands free plant production. Additionally, this system will be used for e-commerce purposes, marking a new area for WPS automation. This custom-designed delivery system will improve labor-productivity and efficiency by optimizing plant-transport and -delivery, key challenges in North America’s fast-scaling greenhouse sector.

“This project is more than a contract—it’s a further step for this market into optimizing productivity and efficiency beyond just internal logistics”, said Conré Oostrom, CEO of WPS. “The Michigan installation marks a significant step toward supporting growers in North America with the next level of smarter, scalable automation.”

Wageningen University & Research, BU Greenhouse Horticulture in Bleiswijk automates its research activities

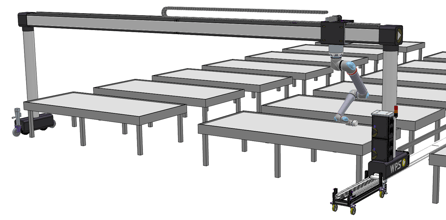

In the same two-week period, WPS secured another prestigious project, together with Bom Group. This time, it's for our phenotyping department and on familiar ground: a state-of-the-art Gantry system equipped with a robotic arm will be delivered to WUR, renowned as one of the world’s top agricultural universities. This Gantry system, the basics of which are also suitable for other plant research goals and even for use among growers, will enable WUR researchers to conduct advanced, automated crop trials with unparalleled precision and consistency in shorter timeframes.

“We are proud that WUR, a global player in agricultural science, has chosen WPS to automate its research facilities in Bleiswijk,” said Oostrom. “Their trust in our technology validates our commitment to quality, adaptability, and future-focused design.”

WPS demonstrates the power of innovation in challenging times

These wins come at a time when many companies are navigating tightening budgets and cautious investment climates. Yet WPS has demonstrated that innovation, reliability, and global relevance remain compelling value propositions, even in uncertain times.

With almost 30 years of experience in smart logistics, WPS continues to set the standard for automation in horticulture and plant research. The recent deals not only reinforce their technical leadership but also represent a broader industry trend: the global horticulture and phenotyping market is leaning increasingly on automation to meet labor shortages, increase sustainability and improve yields.

As the company looks ahead to executing these projects, WPS remains committed to helping growers and researchers worldwide cultivate smarter and more efficient futures.

.jpg)