In many cases customer focus and cost savings don’t complement each other. WPS makes it possible at Van Winden. By using a smart sorting system from WPS, Van Winden can achieve better results, better quality with less labor. Making customers happier while increasing profits.

On our way to 100% Handsfree growing

On our way to 100% Handsfree growing

Tom van Winden; ‘Thanks to WPS we have more overview of our processes. This allows us to better anticipate customer specific requirements. We can also communicate sooner on our product availability. I’m very happy with this progress and I’m not even referring to the labor savings this process brings us. Even more so when you see less available people and the associated rising cost of labor. We’d like to thank WPS for showing us a way to 100% handsfree growing. We are ready for he future!’

Improving internal logistics

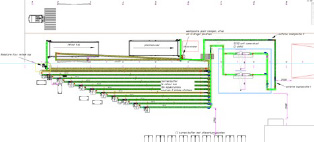

Coming out of the greenhouse the plants are placed with a forklift on a supply conveyor. The plants are spaced into individual plant carriers (OPD). These carriers have been specifically designed to assure stability for the plants while moving through a camera system.

Plants are transported over the WPS conveyors through the camera system, here the plants are evaluated on spikes / leaves. The plants are rotated 360 degrees to get the most accurate classification The images are evaluated by our Vision software which determines to which assortment a plant qualifies. After this the plants are placed in a sorting buffer.

This technology has be successfully been used with phalaenopsis, but here being applied to Zamioculcas

Sorting at WPS packing station

Every sorting is assigned to a packing station, where plants are automatically, without the interference of human hands, are send to. Plants which are not ready for shipment are being redirected towards the greenhouse.

When a packing station seems to get an overflow of product, the WPS software will signal this and allow the operator to assign additional packing stations.

Do you also want happier customers and lower cost. Please reach out to us! Or as Tom van Winden and Berry van der Zwet about their experience.

Please contact WPS sales team for more information.