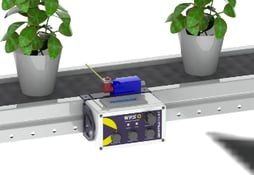

New! SmartFlo Count

To track the performance of your logistics system, to be able to control on input and output, but...

Rainbow Greenhouses is located in Chilliwack, Canada. They have three locations in Western Canada and a new build has started. At the main location the current WPS system is installed in three phases:

The first system was installed in their propagation (for young plants) area. According to Joel this went quite well. It was their first time to install a system partly themselves. They put their maintenance / construction team on it, they worked through things smoothly. Rainbow also connected the propagation area to their sticking area. This is a long route, but because of our SmartFlo track they didn’t have to use the card system.

The feedback that Joel recently received from their grower is that the capacity to loadout material and to loadout plants is significant impacted.

Joel: “the example used was that in the past it would take them a day to pick a truckload and now it takes half a day to pick a truckload. The preparation time to load a truck reduced it almost half, because of SmartFlo. It also proved to be a big benefit in that you can utilize the space better. With SmartFlo you maximize your crop space to the conveyor, and you can always get in to anywhere in the bay to pull the product out. That has been a benefit as well.”

The area of the second phase was almost double in relation to the area that was used during the first phase. It is adjacent and connected to the first phase. This area consist of fifty percent for propagation and the rest of the area is used for annual plants.

Our SmartFlo system was installed in a different area during the third phase. It has its own SmartFlo server. The installation was very easy for Rainbow. The faster moving products have the most benefits. The plants can move very easy between the different climate areas because of SmartFlo.

At Rainbow they are used to do things themselves. Doing it yourself is the attitude and culture at Rainbow. They are used to installing systems themselves. It was the right decision to choose for installation by themselves.

Joel: “it saves us money and it makes sure our guys know the SmartFlo system inside out. For us I would say: without a doubt it makes sense. Just about anybody can do it. It also helps you if you want to install another phase of SmartFlo at your company. Because you did it last time, you can easily do it the next time. Most greenhouse people are hands-on people. They get in there and just do it. This kind of system works for them to do that.

In the first phase it changed to a degree how Rainbow utilized their propagation area. How much and how easy they could utilize it and maximize the space.

“We think the most quantitated we can get is to say is that we can loadout the same amount of product in half the time. The other thing too is moving staff between compartments, that has been made much easier because of SmartFlo. It also helps employees set the pace, regulate their speed.”

“The WPS system has helped us meet our growth objectives. To do more with less and to go further. Having the SmartFlo system in has allowed us to do things with less amount of people and minimize that need."

Rainbow is looking into possibilities to add another 30-50% of SmartFlo into the next stage of their company. They want to connect the data they will gain to see what kind of product they should grow or to see how they should grow it in combination to automation. Rainbow looks forward to adding more SmartFlo systems in order to keep growing.