WPS, a global leader in high-throughput plant handling systems, proudly introduces its latest development in plant research automation, the WPS Phenotyping Gantry.

Traditionally, plant phenotyping is a manual process which is very labor intensive and rather subjective. As today’s environmental challenges ask for scale up in plant research, in order to develop new crops or new products that are able to cope with these challenges, manual phenotyping often forms a bottle neck when scaling up on research.

Industry 4.0 has brought us many new digital and data driven technologies, which are currently still finding their way into plant research. For instance, machine vision is now being adopted to digitally phenotype plants. Whereas Industry 4.0 is very technology centered, Industry 5.0 has now emerged as a new paradigm where emphasis is placed on societal goals and placing the wellbeing of workers at the center of the production process. Automation must work for people rather than replacing them, and contribute to society in a positive way. These same principles can be applied in the process of introducing automation technologies in plant research. Rather than replacing researchers, technology helps plant researchers to focus on making new discoveries and advancing knowledge, unburdened by the limitations of manual phenotyping.

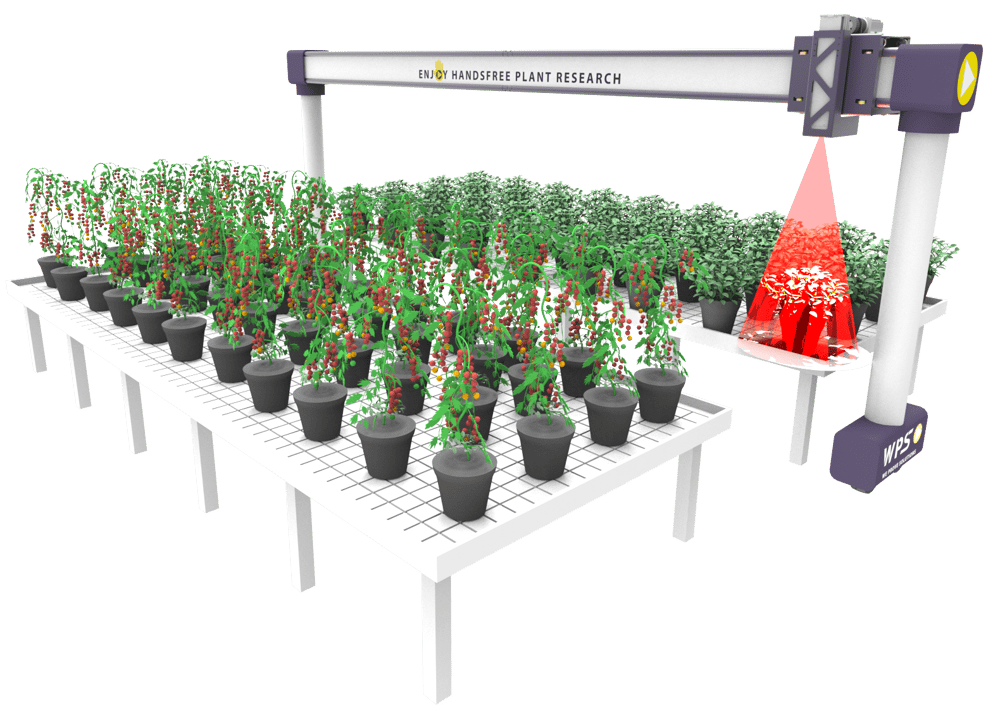

Digital phenotyping offers a data driven and scalable solution, which at the same time reduces subjectivity. Also, by using different sensors one could observe more than the human eye ever could, which further enriches the data being collected. As such, digital phenotyping supports researchers by broadening and improving their toolset. The question is, how do you bring these plants and sensors together? One could take a picture of each individual plant and analyze these pictures digitally. While this reduces subjectivity, this approach still isn’t scalable. To realize a high throughput phenotyping system, one should either bring the plants to the sensor, or the sensor to the plants, fully autonomous. In research facilities plants are often transported towards the sensors, because this allows to observe the plants under controlled conditions. However, this principle is not always applicable. In some cases the crop may not be suitable for frequent transport or the individual plants may be observed with sensors that cannot be moved. Sensor to plant systems offer a useful solution to these situations.

With a broad portfolio of ‘Handsfree Plant Research’ technologies, WPS brings Industry 5.0 to plant research facilities, making them ready for ‘Plant Research 5.0’. Our latest development, the Phenotyping Gantry autonomously brings sensors to the plants to collect data, offering a scalable solution to researchers to keep their hands free and spend more time at making new discoveries and developing knowledge.

"In the age of Industry 5.0, our 'Handsfree Plant Research' technologies are reshaping plant research facilities, ensuring researchers are equipped with the tools they need to thrive in Plant Research 5.0," says Digna van Zanten, CEO at WPS.

The WPS Phenotyping Gantry can be equipped with various sensors, ranging from RGB sensors to 3D sensors and multispectral sensors. As a specialist system integrator, WPS has a broad network of highly experienced partners in the field of sensors and machine vision, allowing to choose the right system for each application.