Ammerlaan-Sosef is a modern potted plant nursery in the heart of horticultural area the Westland. Ammerlaan-Sosef was founded in 1999 after Ard Ammerlaan started working together with son Jeffrey and employee Gertjan Sosef. After Ard’s original crops, pot chrysanthemums and Celosia Caracas, which he had been producing for years, Ammerlaan-Sosef now has an annual program with Primula Sweet Kisses, Cyclamen and Celosia 'Deep Purple' Caracas and a few other Celosias, including the new varieties Javalin and Vintage.

Ammerlaan-Sosef was the winner of the Dutch Flower Award 2018.

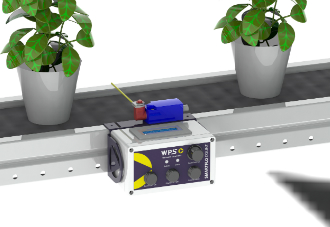

At the Sprongenloet nursery in Honselersdijk, Ammerlaan Sosef grows 6 varieties of Celosia and 13 colors of Primula. In order to further improve logistics in this nursery, they have chosen again for the WPS’ SmartFlo automated transport system.

Crossing

The SmartFlo Crossover, a conveyor belt with a mobile frame, will be used to connect the main and bay belts. Furthermore, extendable parts in the conveyor belt, the SmartFlo Extension tm, will be used to cross the main isle,

Innovation

Ammerlaan Sosef is also one of the first to use the new SmartFlo Count, a flexible counter that allows customers to wirelessly keep track of efficiencies during plant movements in the greenhouse.

Collaboration

WPS and Ammerlaan-Sosef have been working together for several years. With this new deal, the collaboration between the two companies is further confirmed.